Industries Served

Tri-Gon Precision, Inc delivers the highest possible value in the precision parts and services we offer to the industries we serve. Our company’s strength and longevity result from our ability to sustain long-lasting relationships with our customers and vendors.

Our many years of knowledge and experience has allowed us to supply quality components and industrial machining services to a diverse line of industries including, but not limited to:

Department of Defense (DOD)

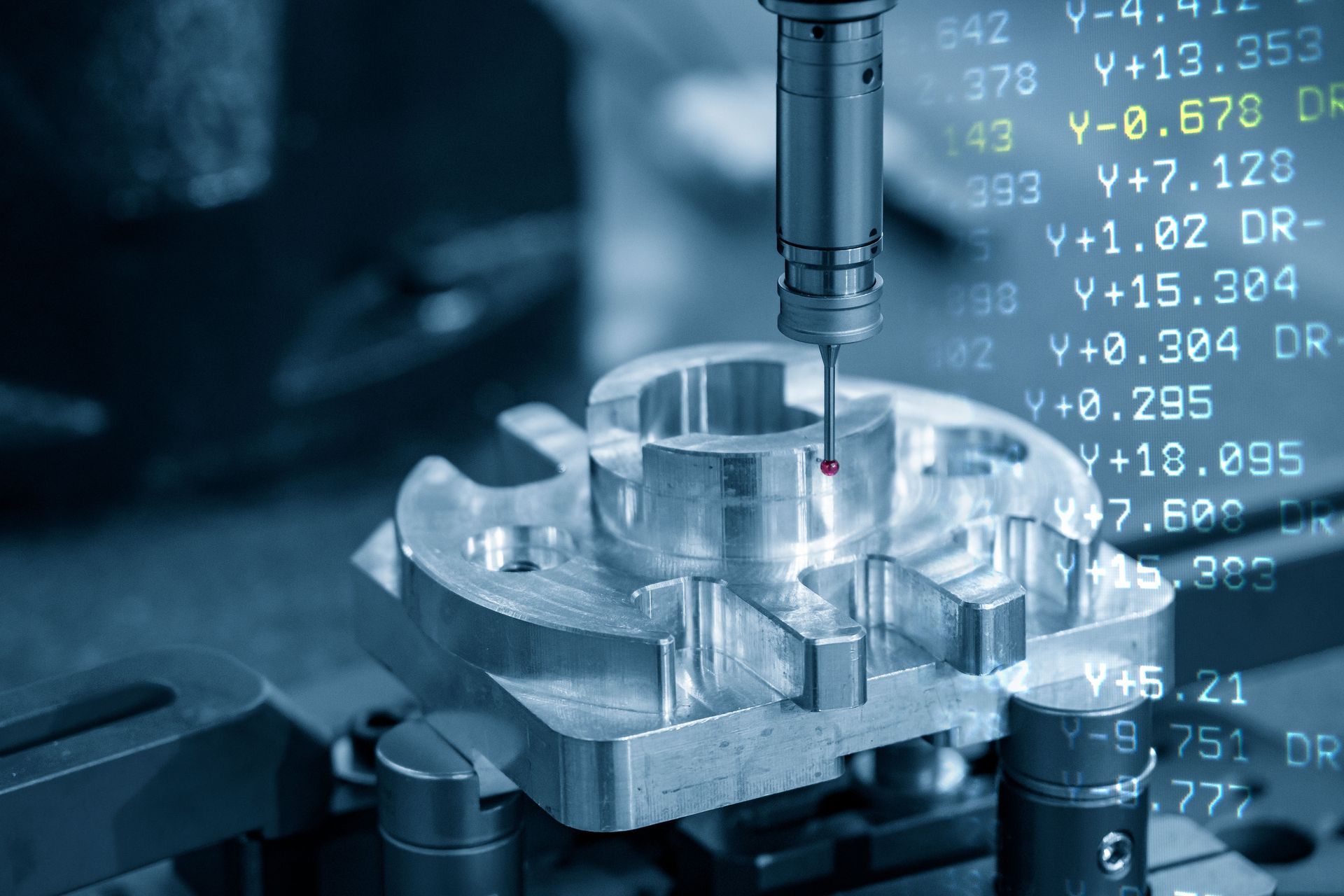

Tri-Gon Precision, Inc has supported the Department of Defense for decades by delivering mission-critical components that meet the strictest military standards. Our ITAR-certified facility specializes in precision CNC milling, turning, grinding, and advanced finishing processes to produce parts with exacting tolerances for aerospace, weapons systems, communications, and navigation equipment. From intricate housings and shafts to miniature gears and high-performance surfaces, we ensure durability, accuracy, and reliability under extreme conditions.

With capabilities including micromachining, laser machining, Swiss screw machining, and comprehensive inspection, we provide secure, high-quality solutions for defense contractors—streamlining production with value-added services such as assembly, coating, and heat treatment. As a SAM-registered supplier, Tri-Gon Precision is trusted to deliver components that perform flawlessly in the most demanding environments.

High Technology

Tri-Gon Precision, Inc delivers ultra-high precision machining for aerospace components, combining CNC milling, turning, laser machining, micromachining, and advanced grinding in our Colorado Springs facility. With tolerances as tight as .000020” and surface finishes down to 1 micro-inch, we create custom parts that meet evolving aerospace demands for accuracy, durability, and performance. Our team works closely with customers to ensure designs are optimized for function and value, providing cost-effective solutions backed by exceptional quality and service.

Medical Industry

Tri‑Gon Precision, Inc delivers mission-critical medical components with zero margin for error. Specializing in CNC and Swiss screw machining, we produce micro pins, surgical connectors, and implants with tolerances down to microns and flawless surface finishes. Our capabilities include ultra-precision grinding, laser drilling, and super-finishing for parts used in surgical tools, implants, robotic systems, and diagnostic equipment. ISO‑9001 compliance, full traceability, and certification ensure every component meets stringent medical standards. Whether you need prototypes or high-volume production, we scale efficiently while maintaining accuracy and cost control. Based in Colorado and serving nationwide, Tri‑Gon partners with OEMs to solve design challenges and deliver precision parts that perform inside the human body or under the surgeon’s eye.

- High Technology

- Computer

- Dental

- Electronics

- Entertainment

- Fortune 500 Companies

- Instrumentation

- Department of Defense (DOD)

- Military

- Mining

- Prime Contractors

- Recreational

- Semi-conductor closed circuit (CCD)

- Telecommunications

Utilizing our expertise in the machining of our customers parts for their products has been exciting to be a part of such products as puzzles to rockets, computers to bicycles, satellites to airplane seats.

The Tri-Gon team continuously researches new technologies in precision machining services to provide products, services and solutions necessary to satisfy our customer needs worldwide. We are deadline driven, never losing sight of your company’s commitments.

The staff at Tri-Gon will work with you to ensure the most cost-effective solution for your precision machining applications. Contact us today to learn more about our capabilities and the material choices we have available.